Legacy Data Conversion

Sindsar, a trusted engineering partner, understands that legacy data is more than just files – it's the foundation of your operational history, intellectual property, and critical business insights. However, outdated formats, fragmented systems, and data inconsistencies can hinder your progress in today's digital landscape.

Our specialized Legacy Data Conversion services empower you to seamlessly migrate your valuable data into modern, efficient systems, unlocking its true potential and driving innovation.

Don't let outdated data hold you back. Partner with Sindsar to transform your legacy data into a valuable asset that drives your digital transformation journey.

Design & Engineering

At Sindsar, we are not just engineers; we are visionaries, innovators, and problem-solvers. Our Design and Engineering services are driven by a passion for pushing the boundaries of what's possible, transforming ideas into reality, and delivering exceptional results.

Our team comprises highly skilled and experienced engineers with diverse backgrounds and expertise in various disciplines. We embrace a culture of innovation, constantly exploring new technologies and approaches to deliver cutting-edge solutions.

Whether you're developing a new product, optimizing an existing system, or tackling a complex engineering challenge, Sindsar's design and engineering expertise can help you achieve your goals.

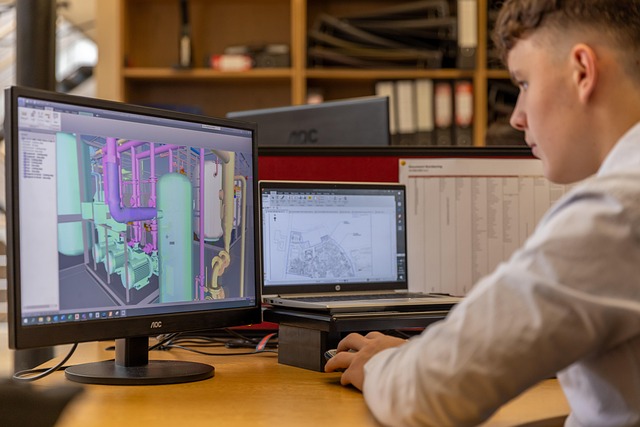

CAD Modeling and Prototyping

In today's fast-paced world of engineering and product development, the ability to quickly and accurately translate ideas into tangible prototypes is essential. Sindsar's CAD Modeling and Prototyping services provide a seamless bridge between conceptualization and realization, enabling you to bring your visions to life.

Our team of skilled CAD modelers utilizes industry-leading software to create precise and detailed 3D models of your products or components. We offer a range of prototyping options, from rapid prototyping techniques like 3D printing to traditional methods like machining and casting, allowing you to test and refine your designs.

Hydraulic & Pneumatic Design

At Sindsar, we specialize in designing and implementing robust and efficient hydraulic and pneumatic systems that meet the unique demands of your application. Our expertise spans a wide range of industries, from manufacturing and construction to aerospace and automotive.

We design and analyze hydraulic and pneumatic systems, considering factors such as pressure, flow, force, and power requirements. We integrate hydraulic and pneumatic systems into larger machinery and equipment, and provide on-site commissioning and start-up support.

Structural Engineering

In the realm of structural engineering, structural integrity is paramount. Sindsar's Structural Engineering services are dedicated to ensuring that structures are not only aesthetically pleasing but also safe, durable, and efficient. We employ a rigorous approach to design, analysis, and construction, ensuring that every project meets the highest standards of quality and safety.

We utilize advanced software and methodologies to analyze and design structures, considering factors such as loads, stresses, and deformations. We design and analyze various building structures, including residential, commercial & industrial buildings and also in the design and analysis of bridges.

New Product Development

In the dynamic field of New Product Development, innovation drives success. Sindsar's NPD services are committed to transforming ideas into market-ready products that are functional, sustainable, and competitive. We adopt a comprehensive approach to ideation, prototyping, and testing, ensuring every product meets the highest standards of quality and performance.

We leverage cutting-edge tools and methodologies to design, simulate, and validate products, considering factors such as usability, manufacturability, and market demands. Our expertise spans diverse industries, enabling us to develop innovative solutions for consumer goods, industrial equipment, and advanced technologies.

Special Purpose Machines

In the specialized domain of Special Purpose Machines, precision and efficiency are critical. Sindsar's SPM services focus on designing and building custom machines tailored to unique industrial needs, ensuring optimal performance, reliability, and productivity. We prioritize a meticulous approach to design, fabrication, and integration, delivering machines that meet the highest standards of quality and functionality.

We utilize advanced engineering tools and techniques to develop SPMs, analyzing factors such as operational requirements, material compatibility, and automation needs. Our solutions cater to a wide range of applications, including manufacturing, assembly, and testing processes across various industries.